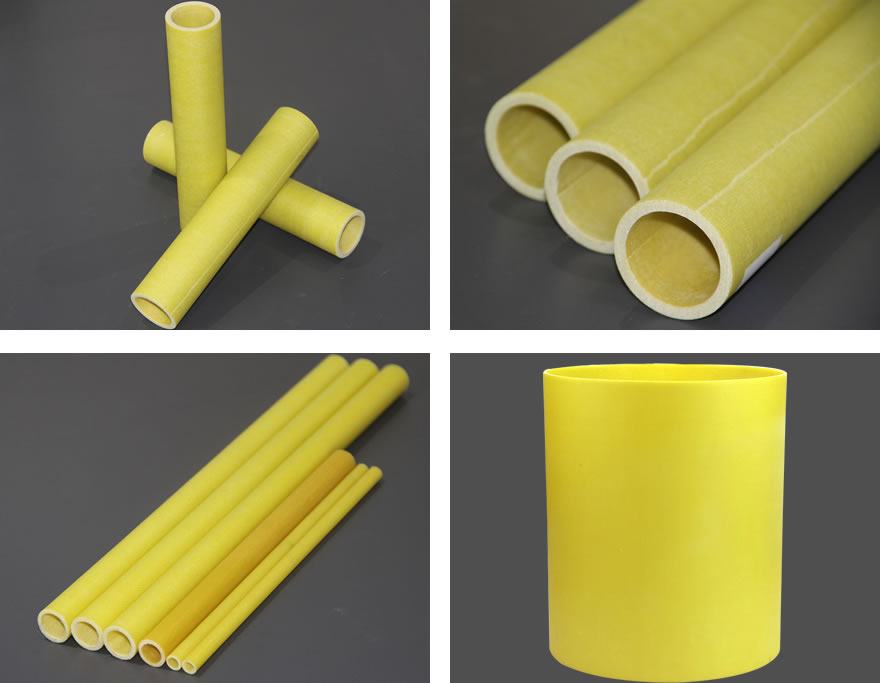

Epoxy fiberglass laminated tube 3640 is tube-like laminated products, which is manufactured by fiberglass cloth impregnated with epoxy resin, and then rolled, baked and cured under heat and hot pressing with good dielectric property and strong machinability.The insulation class is B class and the main color is yellow.

Heat resistance rating: Class F

Wall thickness: ≥1.5mm

Bore Size:6-1200mm

Length:1000-1200mm

Size: Customized

Density: 1.65-1.70

Color: Green and yellow

Application

Epoxy fiberglass laminated tube can be used as insulating structural spares in electrical equipments, and also, can be processed into coil insulation cylinder of try-type transformer and insulation end coil of transformer.

Advantage

3640 Epoxy fiberglass laminated tube produced by Xujue Electrical using fiberglass cloth and epoxy resin as raw material, can be mass-produced with advanced production equipment and automatic production line.

This product has the advantages of reliable quality, smooth appearance, uniform color, neat cutting ends and small thickness tolerance with strict manufacturing technology.

Meanwhile, Xujue Electrical is equipped with advanced ventilation facilities and dust-removing equipment to keep the products dry and clean.

The mechanical and electrical properties of products are superior to the similar one of other companies.

Its quality is recognized by domestic and foreign large enterprises such as Lens Technology in China and Schneider Electric and sold overseas such as European and American areas.

Property Parameter

Executive Standard:JB-T3172-1999(3520) GB-T5132-2009 IEC61212-2006

| Number | Item | Unit | Value |

| 1 | Density | g/cm3 | 1.7-1.8 |

| 2 |

Flexural Strength at Perpendicular Lamination (Under Normal) |

MPa | ≥70 |

| 3 | Axial Compressive Strength | MPa | ≥60 |

| 4 |

Breakdown Voltage at Parallel Lamination (Transformer Oil at 90℃) |

Kv | ≥35 |

| 5 |

Dielectric Strength at Perpendicular Lamination (Transformer Oil at 90℃) |

KV/mm | 14.2 |

| 6 | Dielectric Loss Factor(50Hz) | – | ≤0.03 |

| 7 | Water Absorption | % | ≤1 |

| 8 | Thermal Index | – | 130 |

Product Specification

| Name | Unit | Value |

| Minimum Wall Thickness | mm | 2 |

| Maximum Wall Thickness | mm | 200 |

| Minimum Bore Size | mm | 6 |

| Maximum Bore Size | mm | 1200 |

| Length | mm | 1000-1200 |

FAQ

1.Where is your factory?

Our factory is in Xuchang city, Henan province, China.

2.Can I visit your factory?

Of course, welcome to our factory.

3.Can you send me samples to test?

Yes, we offer free samples to customers and they just need to pay the freight.

4.Do you have any certificates for your products?

Yes, we have UL certificate, SGS, ISO 9001: 2008 etc.

5.What ’s your payment terms?

Usually our payment terms is 30% paid by T / T in advance and the balance paid before shipment. This is negotiable.

6.What ’s your delivery time?

It depends on the product and order quantity. Usually the delivery time is within 7-15 working days after getting deposit.

7.What ’s your main product?

We supply all kinds of insulation materials used in electrical field and most of them used in transformers and motors.