What Should Be Considered When Using Epoxy Rods

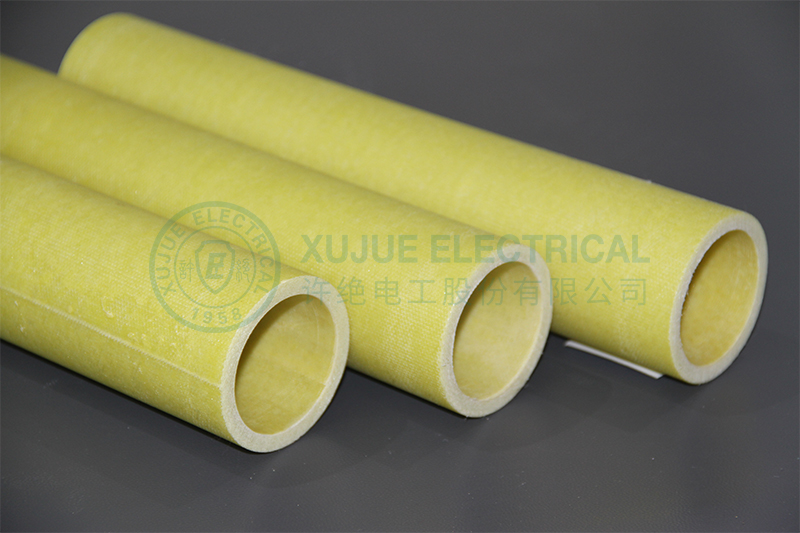

Epoxy rods are a common high-performance insulating material widely used in transformers, switchgear, reactors, new energy equipment, and various power and electrical systems. They offer excellent electrical insulation, mechanical strength, and thermal resistance, playing an important role in engineering applications. However, improper selection or incorrect use may lead to insulation failure, structural damage, or equipment malfunction.

This article explains the key considerations when using epoxy rods from the perspectives of selection, installation, machining, operating environment, and maintenance.

Proper Selection Is the Basis for Performance

Different operating conditions place different performance requirements on epoxy rods. The following factors should be carefully evaluated during selection:

1. Electrical Performance Matching

Whether the dielectric strength meets the system voltage requirements

Whether volume resistivity and arc resistance comply with insulation safety standards

Suitability for AC, DC, or high-frequency operating conditions

For high-voltage or long-term operating equipment, epoxy rods with higher electrical strength ratings should be selected.

2. Mechanical Strength and Structural Requirements

Whether bending strength and compressive strength meet load-bearing requirements

Whether the rod is used as a support, tie rod, or structural fixing component

Stability under long-term vibration or impact conditions

When epoxy rods are used as structural components, selection should not be based solely on insulation standards; mechanical performance must also be evaluated.

Operating Environment Affects the Service Life of Epoxy Rods

1. Temperature Control

Epoxy rods usually have defined thermal classes (such as Class B, Class F, and Class H). Long-term operation above the rated temperature limit may result in:

Accelerated resin aging

Reduced mechanical strength

Degradation of insulation performance

The actual operating temperature should always remain within the specified long-term temperature limit.

2. Moisture and Corrosion Protection

Although epoxy rods have certain moisture resistance, special attention is required in the following environments:

High-humidity or condensation-prone conditions

Exposure to oil mist, acids, alkalis, or other chemical media

Outdoor or semi-enclosed installations

When necessary, materials with low water absorption should be selected, or additional protective structures should be applied.

Considerations for Machining and Installation

1. Machining Methods

During cutting, drilling, or turning, attention should be paid to:

Using dedicated tools to prevent chipping or cracking

Controlling machining temperature to avoid local resin carbonization

Maintaining smooth machined surfaces to reduce stress concentration

Improper machining can significantly shorten the service life of epoxy rods.

2. Installation Process

During installation, the following should be considered:

Avoid forced bending or twisting

Ensure uniform load distribution at fixing points to prevent excessive local stress

Check whether insulating pads are required at contact points with metal components

Operation and Maintenance Considerations

1. Regular Inspection of Insulation Condition

Check for surface cracks, whitening, or carbonization

Look for signs of partial discharge

Verify that fixing structures remain secure

2. Avoid Overload and Abnormal Operating Conditions

Short-term abnormalities may be difficult to detect, but long-term accumulation can significantly reduce the service life of epoxy rods.

Importance of Choosing a Reliable Supplier

High-quality epoxy rods should feature:

Stable and consistent raw material systems

Mature forming and curing processes

Complete and reliable performance test data

Compliance with third-party testing or relevant industry standards

In power and industrial systems, material stability is often more critical than any single performance parameter.

Epoxy rods are not universal materials. Their performance depends on proper selection, standardized machining, correct installation, and suitable operating environments. Only by paying attention throughout the entire application process can their advantages in insulation and structural support be fully realized, ensuring the long-term, safe, and stable operation of electrical equipment.