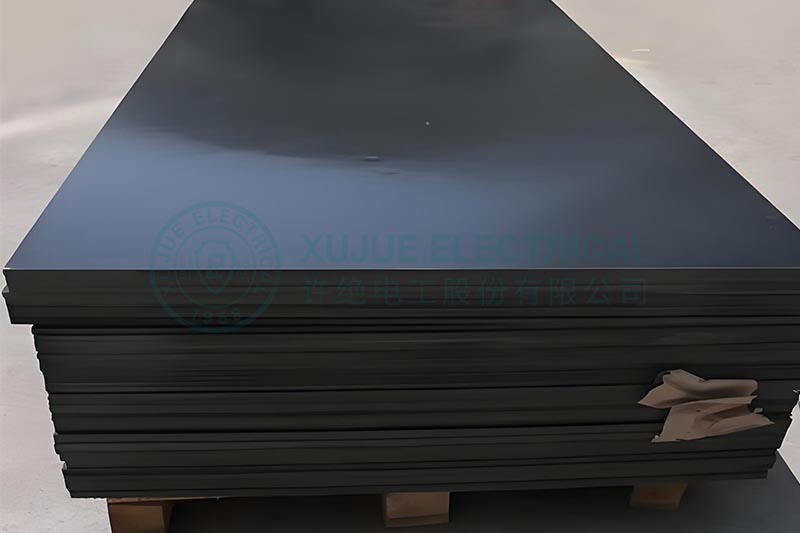

Industrial-Grade G10 Sheet for Solar Panels

With the rapid development of the global new energy market, the performance of core materials in solar photovoltaic modules directly affects the system's operating efficiency and lifespan. Industrial-grade G10 solar panels, due to their excellent mechanical strength, insulation properties, and weather resistance, have become a commonly used material in photovoltaic module manufacturing and export. This article will introduce industrial-grade G10 solar panels from the aspects of performance characteristics, main advantages, and application areas, helping companies improve the quality and reliability of photovoltaic products.

What is an Industrial-Grade G10 Solar Panel?

G10 is an epoxy fiberglass composite board, made by impregnating fiberglass cloth with epoxy resin and then curing it under high temperature and pressure. As a dedicated panel material for photovoltaic modules, its main functions include the following three aspects:

Electrical Insulation: Ensuring the safe operation of the internal circuitry of the photovoltaic module

Mechanical Support: Improving the module's impact and bending resistance

Environmental Protection: Blocking moisture, dust, and ultraviolet radiation from corroding the solar cells.

Industrial-grade G10 backsheets are typically certified by IEC and relevant international photovoltaic standards, ensuring stable performance and suitability for various operating environments.

Performance Characteristics of Industrial-Grade G10 Solar Panels

Excellent Electrical Insulation

This material has high dielectric strength, ensuring long-term safe operation of the modules.

Its low water absorption reduces the risk of leakage in humid environments.

High Mechanical Strength and Impact Resistance

It possesses good flexural strength and compressive strength, and is capable of withstanding mechanical stress during transportation, installation, and long-term outdoor use.

Stable Weather Resistance

G10 backsheets can withstand high temperatures and extreme climatic conditions.

Its excellent UV resistance and corrosion resistance prevents discoloration or delamination over long-term use.

Good Processing and Dimensional Stability

G10 backsheets offer precise thickness and dimensional control, facilitating processing and assembly to meet the design requirements of various photovoltaic modules.

Advantages of Industrial-Grade G10 Solar Panels

Reliable Performance: Electrical and mechanical properties of G10 backsheets remain stable during long-term use.

High Safety: G10 backsheets help avoid safety hazards such as short circuits and electric shocks.

Flexible Processing: G10 backsheets thickness, dimensions, and surface treatments can be customized according to customer needs.

Compliant with International Standards: The G10 backsheet has obtained certifications from IEC and UL, meeting the requirements of both domestic and international markets.

Industrial-Grade G10 Solar Panel Applications

Solar Photovoltaic Modules: Serves as the backsheet for solar panels, providing insulation and mechanical support.

Energy Storage Systems: Protects energy storage battery packs and ensures electrical safety.

New Energy Equipment: Used as insulation components in wind-solar hybrid systems and outdoor power equipment.

Export Photovoltaic Projects: Complies with international standards such as IEC, suitable for large-scale industrial projects and overseas engineering.

How to Evaluate and Select G10 Solar Panels?

Certification and Test Reports:

Confirm that the product has passed certifications such as IEC 61215, IEC 61730, and UL 1703, and has a third-party long-term aging test report.

Material Information Transparency:

Require suppliers to provide complete material specifications to ensure the absence of hazardous substances.

Real-World Case Studies:

Examine projects that have been operating for 3-5 years to understand the product's long-term performance.

Manufacturer Reputation:

Choose manufacturers with strong R&D capabilities, a sound quality control system, and a good industry reputation.

Cost-Benefit Analysis:

Comprehensively consider procurement costs, service life, performance degradation, and maintenance requirements to assess the total lifecycle cost.

Industrial-grade G10 solar panels, with their excellent electrical properties, mechanical strength, and weather resistance, have become an important material in the photovoltaic industry. Through continuous improvements in materials and processes, they provide effective protection for photovoltaic modules. For photovoltaic projects that prioritize long-term reliability, power generation efficiency, and return on investment, G10 solar panels have become a reasonable choice.

If you require high-quality industrial-grade G10 solar panels, we can provide standard specifications and customized size solutions to meet the needs of photovoltaic modules, energy storage systems, and new energy equipment. Please contact us for detailed technical parameters, samples, and quotations to support the efficient and safe operation of your projects.

- Pre:What Should Be Considered When Using Epoxy Rods

- Next:sorry!