Reliability Analysis of G10/FR4 Epoxy Sheets Used in Generators

In the field of generator manufacturing and maintenance, material selection directly determines equipment performance, service life, and operational safety. G10/FR4 epoxy sheets are high-performance insulation materials and constitute core insulating components in modern generator design. This article provides a technical analysis of the reliability of G10/FR4 epoxy sheets in generator applications, offering data-supported professional reference for equipment designers, maintenance engineers, and industry decision-makers.

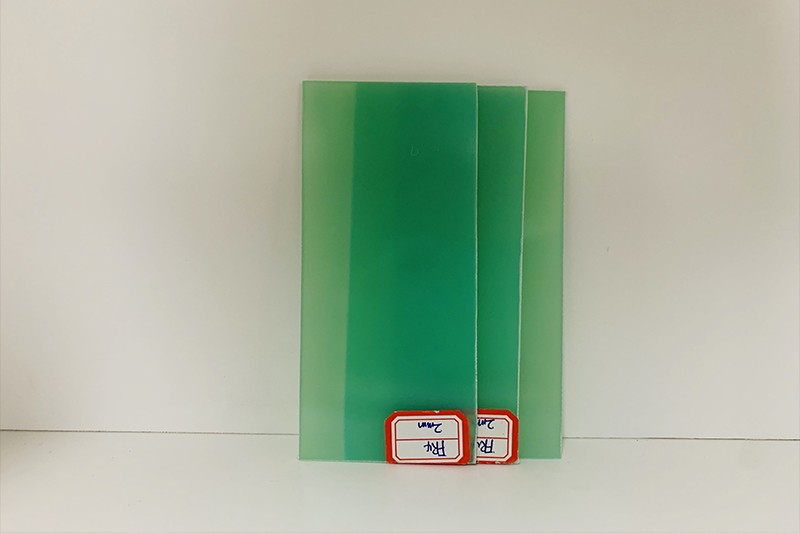

Basic Concept of G10/FR4 Epoxy Sheets

G10/FR4 are glass-fiber-reinforced epoxy resin laminated sheets featuring excellent mechanical strength, electrical insulation, and environmental resistance. FR4 denotes Flame Retardant Grade 4. And the material complies with the UL94 V-0 flame-retardant standard, meeting the core safety requirements for generator operation.

Main Application Scenarios of G10/FR4 Epoxy Sheets in Generators

Insulating gaskets and spacers

Winding supports and end-winding fixing components

Slot wedges and gap shims

Terminal boards and connector insulation parts

Brush holders and brush support structural components

Reliability Analysis of G10/FR4 Epoxy Sheets

1. Electrical Insulation Performance

G10/FR4 exhibits a dielectric strength of 20–40 kV/mm in dry environments and maintains excellent insulation performance even under humid conditions. This effectively prevents inter-winding short circuits and ground faults, making it suitable for high-voltage generator equipment.

2. Mechanical Strength and Stability

Strength-to-weight ratio: Flexural strength up to 415 MPa, providing structural support without significantly increasing overall equipment weight

Dimensional stability: Coefficient of thermal expansion of 12–16 ppm/°C, maintaining dimensional stability under temperature fluctuations and reducing thermal stress

Fatigue resistance: Capable of withstanding vibration and cyclic mechanical stresses during generator operation

3. Thermal Performance

Continuous operating temperature range: 130–155°C, suitable for most generator operating conditions

Thermal conductivity: approximately 0.3 W/(m·K), offering moderate thermal management capability

Glass transition temperature (Tg): not lower than 130°C, ensuring stable mechanical performance in high-temperature environments

4. Environmental Resistance

Moisture resistance: 24-hour water absorption below 0.1%, with no significant degradation of electrical properties in humid environments

Chemical resistance: Resistant to most oils, coolants, and cleaning solvents

UV resistance: Suitable for generator external components that may be exposed to sunlight

5. Flame-Retardant Safety Performance

FR4 epoxy sheets comply with the UL94 V-0 flame-retardant standard, effectively suppressing flame propagation and providing fire protection for generators under fault conditions.

6. Long-Term Aging Characteristics

Accelerated aging test data under simulated generator operating conditions show:

Electrical strength retention ≥ 85% after 20 years

Mechanical property degradation ≤ 15% under normal operating conditions

Long-term stability of surface resistivity, preventing abnormal leakage current increase

Best Practices and Considerations

1. Standardized Application Requirements

Machining: Use tungsten carbide or diamond tools to prevent delamination

Installation: Ensure clean, contaminant-free surfaces; avoid oil or grease that may reduce insulation performance

Thickness selection: Choose appropriate thickness based on voltage rating and operating temperature

Fastening design: Use matching washers and avoid over-tightening to prevent compressive damage

2. Potential Limitations and Mitigation Measures

For continuous operation above 155°C, higher-temperature-rated insulation materials should be used

Strong alkaline environments may affect long-term performance. Additional protective measures are recommended

Seal material edges to prevent moisture ingress

3. Maintenance and Service Life Management

Routine inspections: Check for surface carbonization, cracks, delamination, and other physical damage

Diagnostic tests: Periodic insulation resistance (IR) and polarization index (PI) testing

Service life: Under standard operating conditions, G10/FR4 components can achieve a service life exceeding 20 years

Replacement criteria: Replace components when insulation resistance decreases by ≥50% or when significant mechanical damage is observed

G10/FR4 epoxy sheets demonstrate excellent overall reliability in generator applications. Their balanced electrical, mechanical, thermal, and environmental performance makes them a preferred insulation material in modern generator design. Through standardized material selection, processing, and installation practices, generator components using G10/FR4 can achieve decades of stable operation, reduce maintenance frequency, and enhance overall system safety.