The Environmental Advantages of G10 Epoxy Sheet in Electrical Equipment Insulation

In today's industrial environment, which prioritizes sustainable development, electrical equipment manufacturers must not only ensure product performance meets standards but also prioritize environmentally friendly materials. G10 epoxy sheet is a classic insulation material, and due to its inherent environmental characteristics, it has become the industry's preferred material. This article will analyze the environmental advantages of G10 epoxy sheet when used in electrical equipment insulation and how it can help companies achieve green manufacturing goals.

What is G10 epoxy sheet?

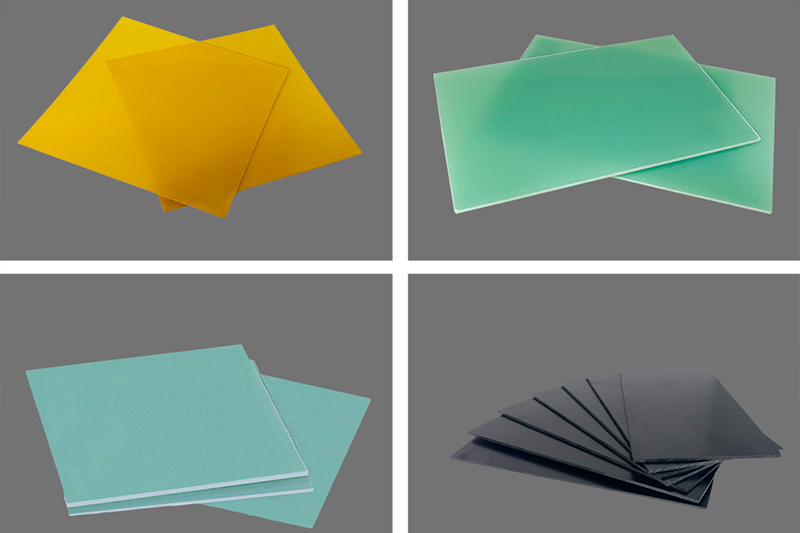

G10 epoxy sheet is a composite material made from electronic-grade fiberglass cloth and flame-retardant epoxy resin laminated at high temperatures. It offers excellent mechanical strength, electrical insulation properties, and chemical resistance. And it is widely used in transformer insulation components, circuit breaker linings, motor slot wedges, and various electrical equipment structural components.

Six Environmental Advantages of G10 Epoxy Sheet

1. RoHS Compliance and Halogen-Free Requirements

Current G10 epoxy sheet, particularly FR-4 grades, strictly adheres to the EU RoHS (Restriction of Hazardous Substances) directive, strictly controlling the content of hazardous substances such as lead, mercury, and cadmium. Furthermore, the halogen-free formula of G10 board does not release toxic halogenated gases during combustion, reducing potential harm to the environment and human health.

2. Durability and Long Service Life

G10 epoxy board offers excellent weather resistance, moisture resistance, and aging resistance, ensuring the long-term, stable operation of insulation components in electrical equipment, even in harsh environments. This extended service life reduces component replacement frequency, thereby reducing material consumption and waste generation.

3. Excellent High-Temperature Stability

G10 material can withstand continuous operating temperatures up to 130°C (some grades can reach 155°C). Its excellent thermal stability helps electrical equipment maintain efficient operation. Stable insulation performance reduces energy loss, thereby helping to improve overall energy efficiency.

4. Recycling and Waste Management

Although G10 epoxy sheet is a thermoset material and can be challenging to recycle, the industry has developed a variety of solutions:

· Physical recycling: G10 epoxy sheet is shredded and used as filler in other composite materials.

· Pyrolytic recycling: G10 epoxy sheet is decomposed in a controlled environment to recover glass fiber and energy.

· Co-processing: G10 epoxy sheet is used as an alternative fuel or raw material in facilities such as cement kilns.

5. Continuously Reducing Environmental Impact

G10 epoxy sheet manufacturers are continuously optimizing their production processes to reduce environmental impact through the following methods:

· Replacing chemical solvents with water-based cleaning agents.

· Utilizing closed-loop water recirculation systems to reduce water consumption.

· Using resin systems with low volatile organic compounds (VOCs).

· Optimizing energy management systems to reduce carbon emissions.

6. Lightweighting

G10 material has a high strength-to-weight ratio, making it suitable for lightweight designs. In electrical applications in mobile devices and transportation, reduced weight directly reduces energy consumption and emissions.

Recommendations for Choosing Environmentally Friendly G10 Epoxy Sheet

When selecting G10 epoxy sheet for electrical equipment, consider the following environmental factors:

Prioritize certified products: Choose products that are UL certified, RoHS compliant, and offer halogen-free options.

Evaluate supplier qualifications: Find out whether the supplier has environmental management system certification (such as ISO 14001).

Consider the full lifecycle impact: Evaluate the overall environmental impact from raw material procurement to end-of-life disposal.

Match application requirements: Select the appropriate environmental rating based on specific application needs to avoid wasteful overdesign.

G10 epoxy sheet offers significant environmental advantages for electrical equipment insulation due to its long service life, halogen-free formula, RoHS compliance, and continuously optimized manufacturing processes. With the promotion of the circular economy concept and the strict implementation of environmental regulations, choosing environmentally friendly insulation materials such as G10 is not only a technical decision but also a reflection of a company's commitment to social responsibility and sustainable development. By properly selecting and applying G10 epoxy sheets, electrical equipment manufacturers can significantly reduce environmental impact while ensuring product performance, supporting the construction of greener and more efficient electrical infrastructure.