DMD Insulation Paper: Performance, Applications, and Benefits in Transformers

In the complex internal structure of power transformers, various materials play a critical role. Among them, DMD insulation paper, as a composite insulation material, has become an indispensable core component in the design of modern transformers, particularly dry-type and oil-immersed transformers. This article will delve into the exceptional performance, wide range of applications, and significant benefits it brings to transformer manufacturing and operation.

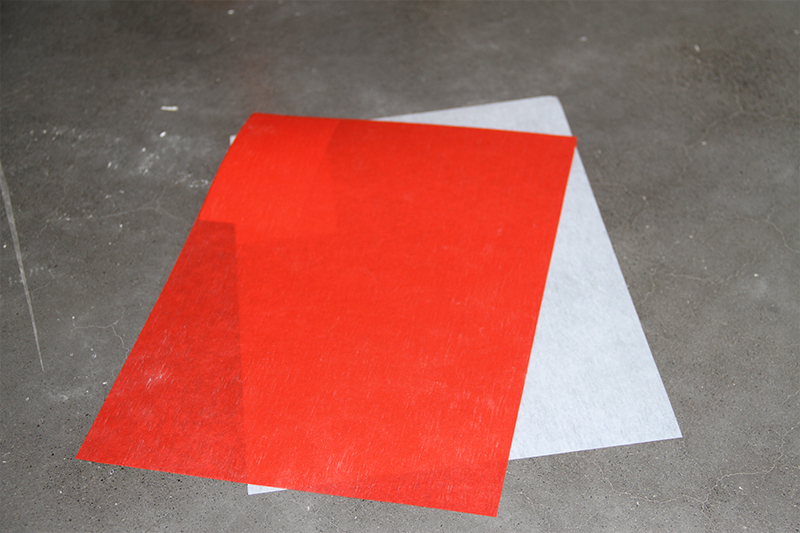

What is DMD insulation paper?

DMD insulation paper is a three-layer composite flexible insulation material, named after its structural composition:

D - Polyester nonwoven fabric (Dacron/Mylar)

M - Polyester film (Mylar)

D - Polyester nonwoven fabric (Dacron/Mylar)

This "sandwich" structure cleverly combines the excellent electrical insulation properties of polyester film with the superior mechanical strength and impregnation properties of polyester nonwoven fabric, resulting in a comprehensive, stable, and reliable insulation material.

Key Performance of DMD Insulation Paper in Transformers

The key to DMD insulation paper's widespread use in transformers lies in its exceptional performance:

1. Excellent Electrical Insulation:

The polyester film layer in the middle possesses extremely high dielectric strength, effectively resisting high electric field intensities and preventing breakdown between windings, ensuring safe and stable transformer operation.

2. Excellent Mechanical Strength:

The non-woven fabric layers on both sides impart excellent tensile strength, tear resistance, and toughness to DMD insulation paper. This allows it to withstand significant mechanical stress during transformer winding, compaction, and operation without breaking, ensuring the integrity of the insulation structure.

3. Reliable Heat Resistance:

DMD insulation paper is typically classified as Class B (130°C), Class F (155°C), or Class H (180°C) insulation material. It can withstand the high temperatures generated during transformer operation, effectively slowing thermal aging and extending the service life of the equipment.

4. Excellent Impregnation and Compatibility:

For oil-immersed transformers, the porous non-woven fabric layer of DMD insulation paper facilitates oil penetration, creating a more complete oil-paper composite insulation system.

For dry-type transformers, it also bonds well with impregnating varnishes such as epoxy resin, achieving void-free, sealed insulation.

5. Strong Chemical and Moisture Resistance:

Polyester material exhibits excellent resistance to most chemicals and solvents and has low moisture absorption, maintaining stable performance, especially in humid environments.

Main Applications of DMD Insulation Paper in Transformers

DMD insulation paper offers exceptional flexibility, covering virtually all areas requiring insulation within a transformer:

Coil insulation: Its primary application is as interlayer insulation, interturn insulation, and outer sheath insulation within the coil.

Spacer insulation: Used to separate coils of different voltage levels (e.g., between high-voltage and low-voltage coils).

End insulation and spacers: Applied to coil ends, they provide mechanical support and insulation.

Lead insulation: Wraps and secures lead wires to prevent discharge to ground or other components.

DMD insulation paper is a preferred material for coil insulation in both oil-immersed and dry-type transformers.

Significant Benefits of Using DMD Insulation Paper

Selecting DMD insulation paper in transformer design offers multiple benefits to manufacturers and end users:

1. Its comprehensive electrical and mechanical properties significantly reduce the risk of transformer failure due to insulation faults, ensuring the safety of the power grid and power-consuming equipment.

2. Its excellent heat and aging resistance extend the transformer's operating life, reducing the frequency and cost of equipment replacement.

3. DMD insulation paper has high dielectric strength, allowing thinner materials to be used for the same insulation grade, facilitating the design of smaller, more compact transformers with higher power density.

4. DMD is soft,which makes it easy to cut, punch, and wind. This simplifies the winding process and improves manufacturing efficiency and consistency.

5. Although DMD insulation paper is more expensive per unit than standard insulation paper, its improved reliability, extended lifespan, and reduced maintenance requirements offer a more competitive total cost of ownership (TCO).