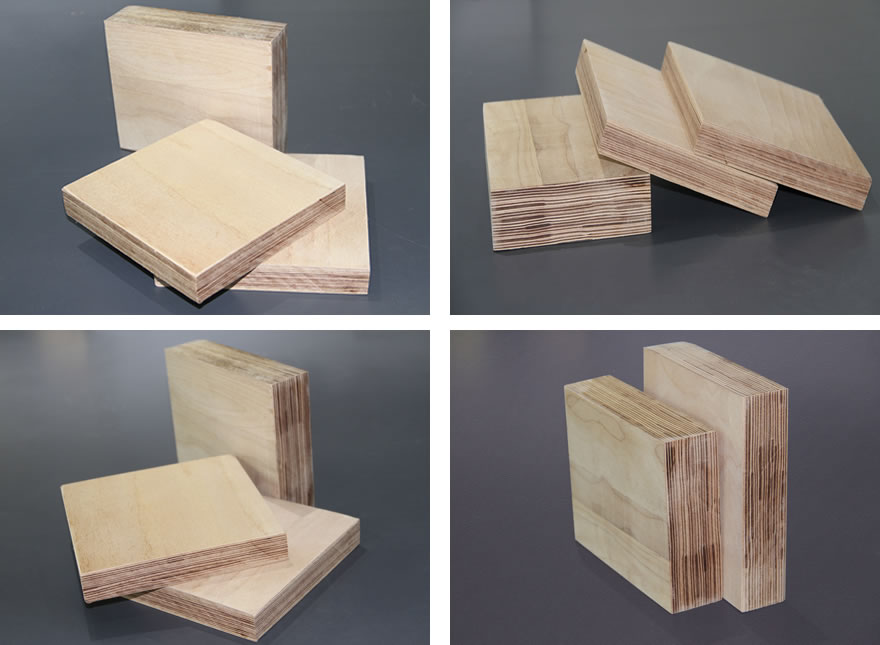

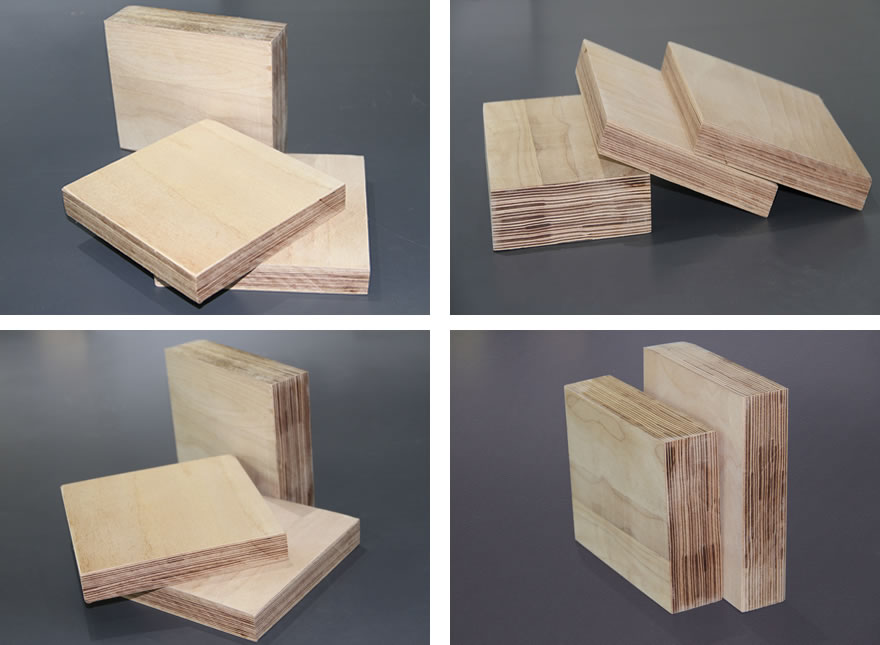

Electrical Laminated Wood Board is made of good birch that is rotarily cut into thin wood layer and then dried, laminated and hot pressed. It has moderate density and high mechanical strength and it is easy to be dried in vacuum and to be processed. The dielectric constant is close to the transformer oil.It can be used for the production of coil plate, core pad, lead bracket and other insulation/support components in transformers or mutual inductor.

Electrical Laminated Wood standard sizes

Transformer Wood Board:

Length* width: 2000mm*1000mm, 2500mm*1250mm, 3000mm*1500mm, 4000mm*2000mm

Thickness: 8mm-150mm

Other sizes are available upon request. For each size, a minimum order of 1,000 kg per delivery is required.

Strengths and Tolerances

Our Laminated Transformer Wood sheets in special and custom sizes are delivered with a tolerance conforming to the DIN 40603 standard or with a very precise strength tolerance after surface finishing.

Electrical Laminated Wood Features

• good electrical insulation

• very good oil absorption

• low specific weight

• withstands high mechanical loading

• low- and high-temperature resistance

• resistance to abrasion and wear

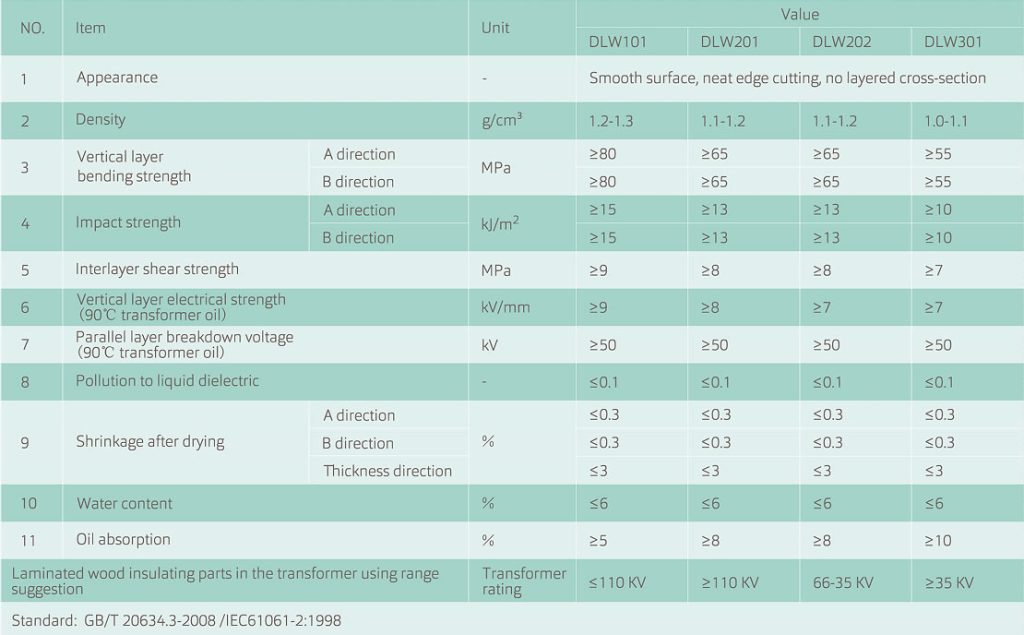

Electrical Laminated Wood Parameter

Laminated Transformer Wood – Finished/Machined Parts

The production of CNC machined components from laminated transformer wood sheets as per drawings from customers is our specialty. We utilize versatile modern CNC milling machines, special laces and automatic machines.

Warehose &Package

International Standard Packaging for Sea Transportation

70MM height non fumigation pallet for the easier of fork. Surface of products are well protected from moisture by 2 layers of clean wrap. The pack was fully covered by 2mm thick wood board to prevent damage.

Transportation and storage

The products should be stacked flat during transportation and storage, and should be transported in clean, dry, canopied vehicles to prevent damage and contamination. They should not be exposed to moisture, rain or sunlight.

When storing, they should be stacked according to categories and specifications in a dry and clean room at a temperature not exceeding 40°C, and placed flat on pads at least 50mm above the ground. They should not be close to fire or heat sources, and each pile should be marked accordingly.